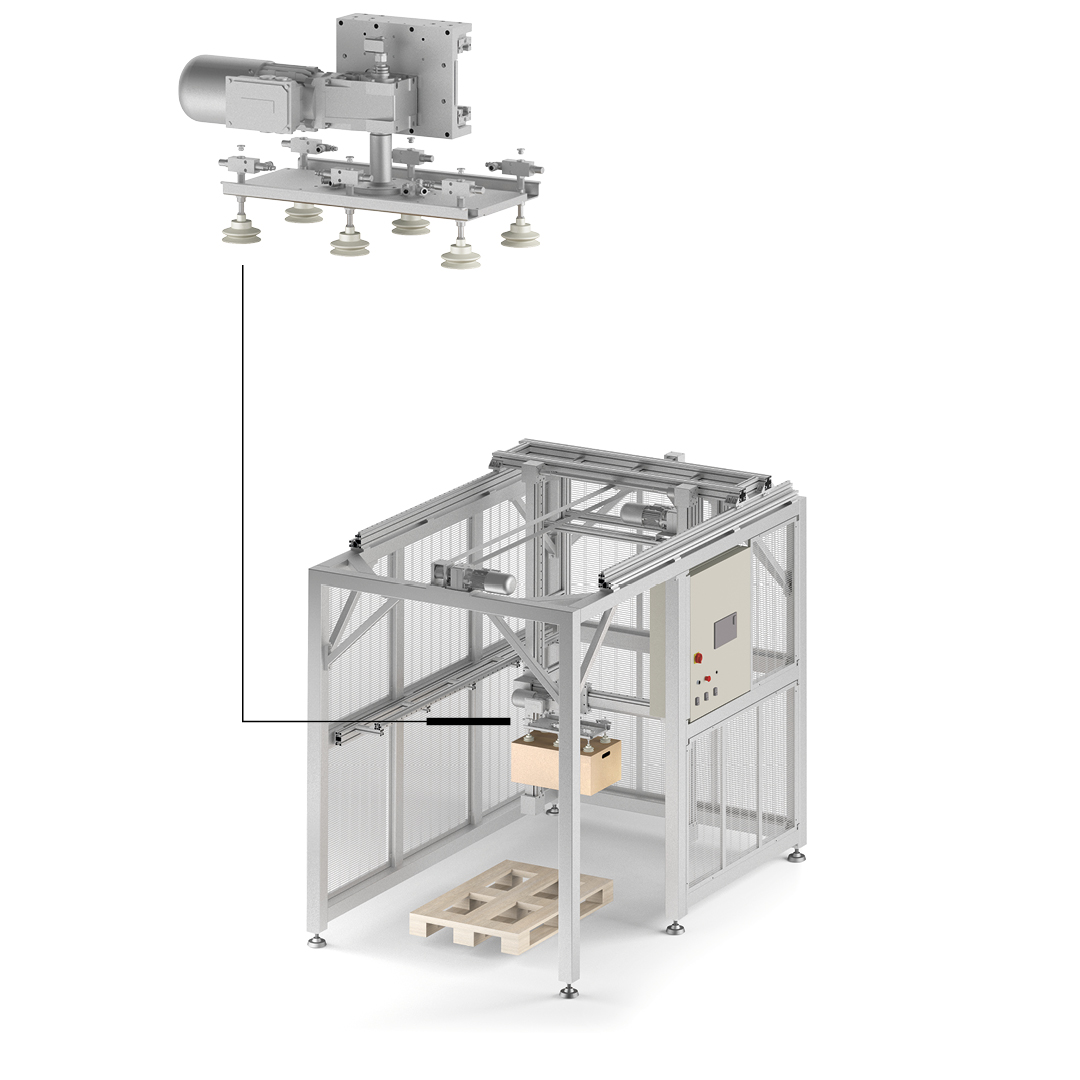

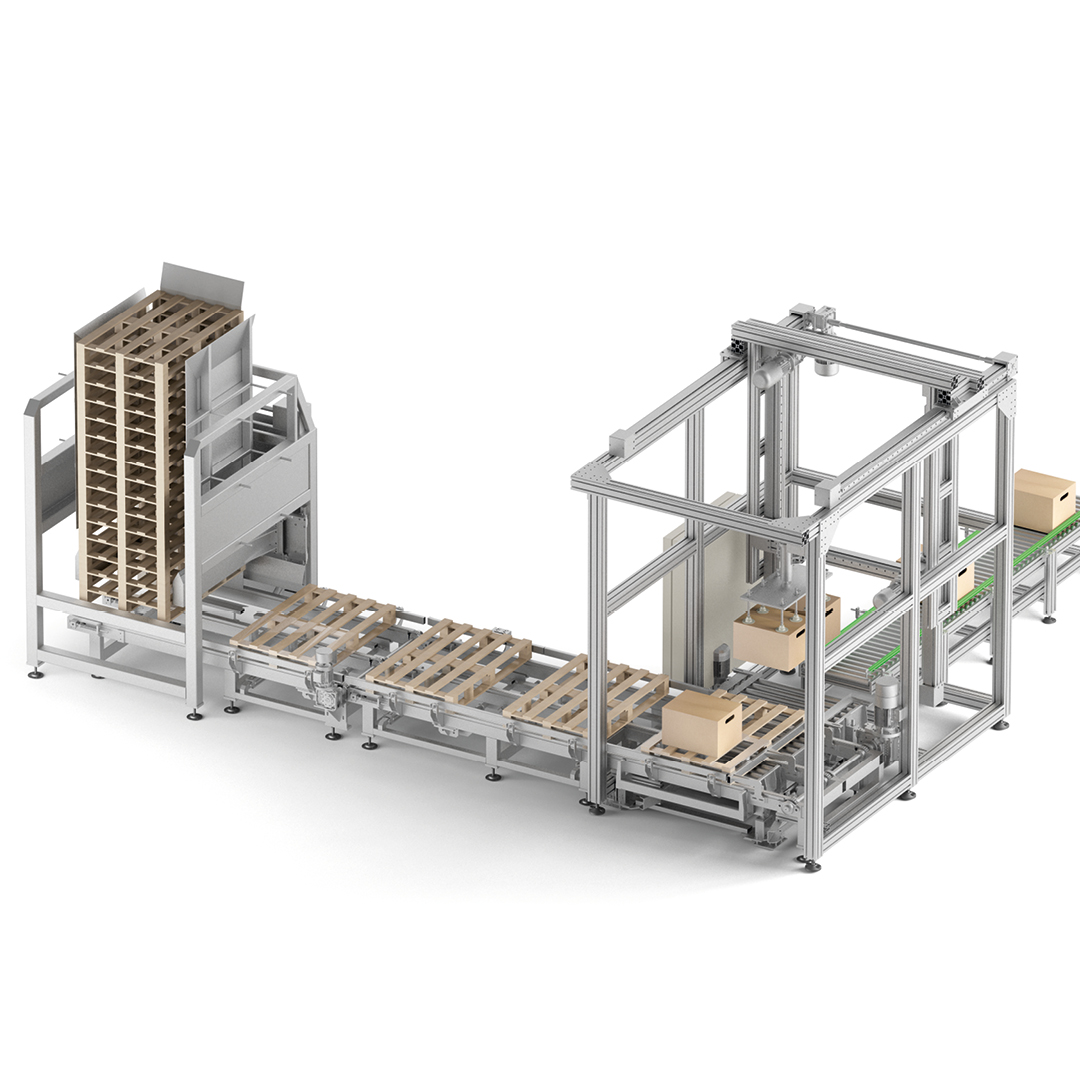

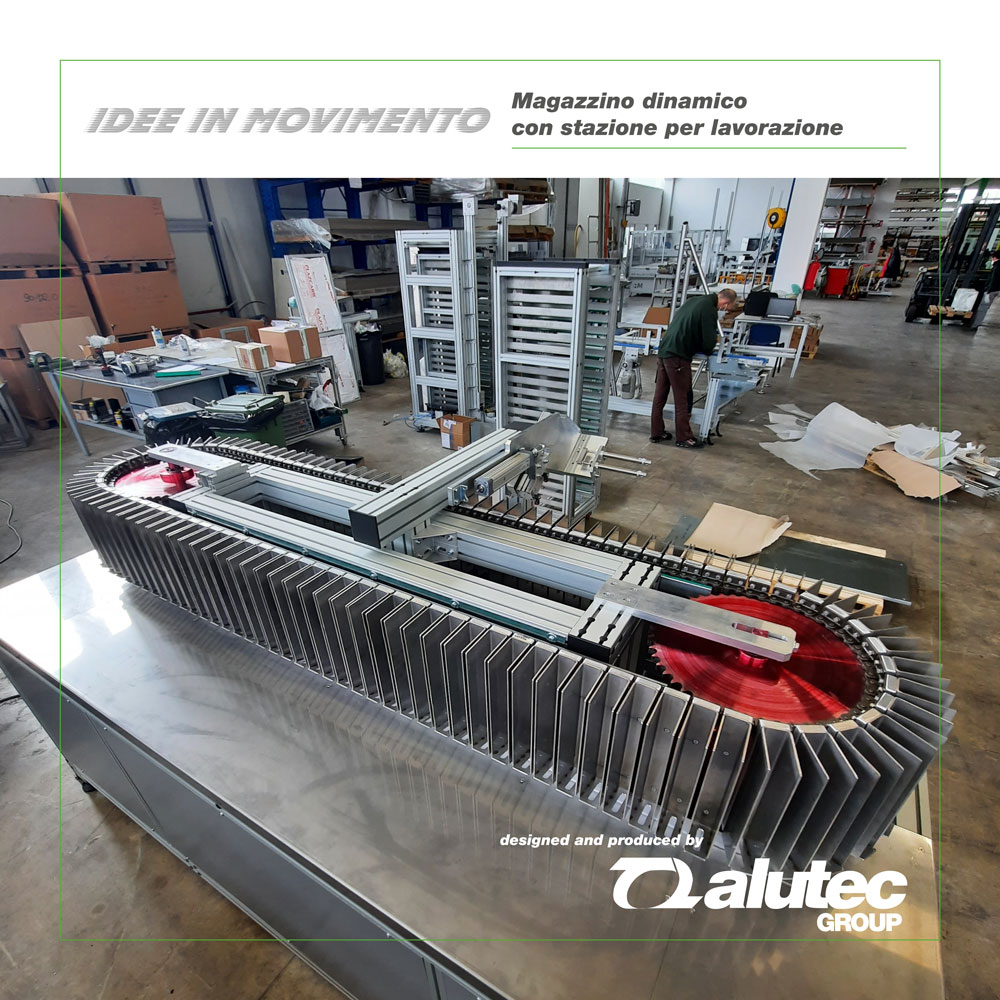

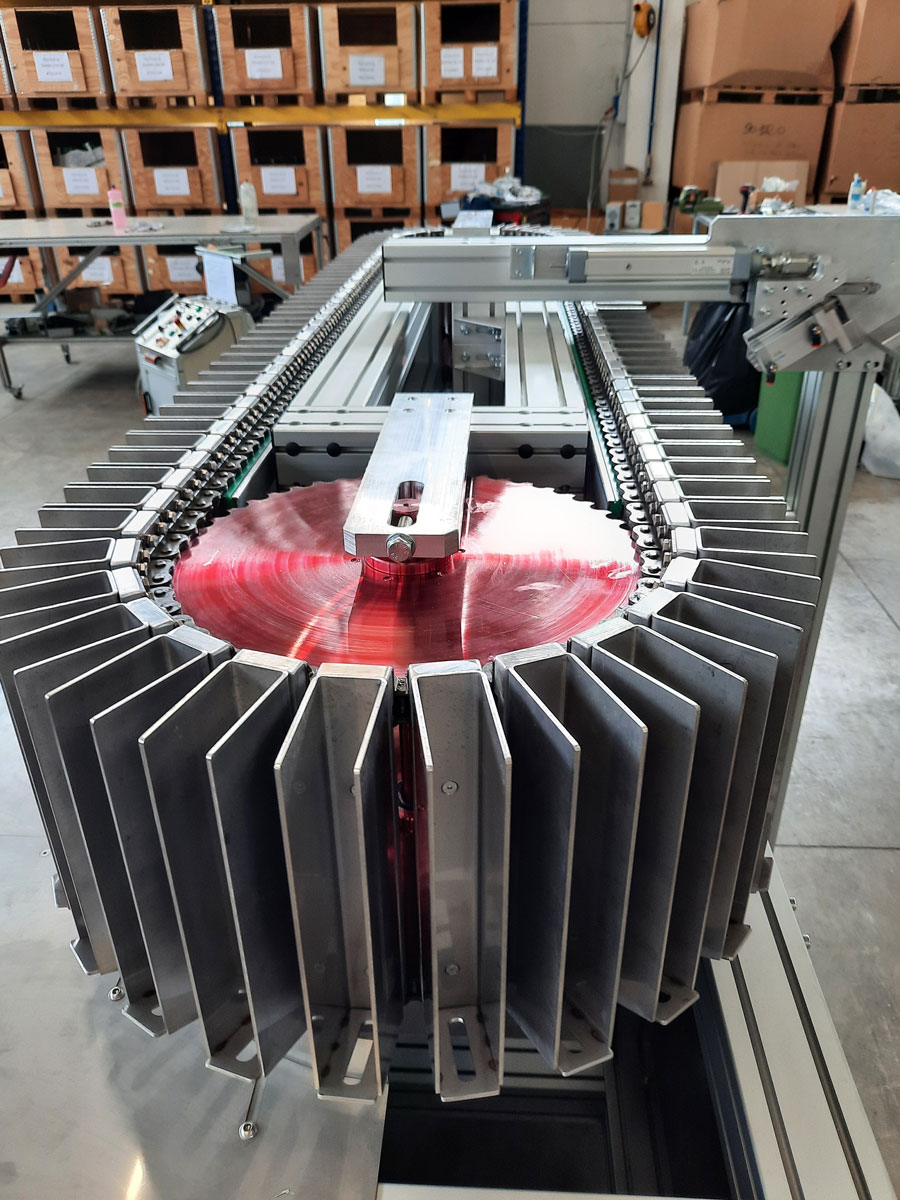

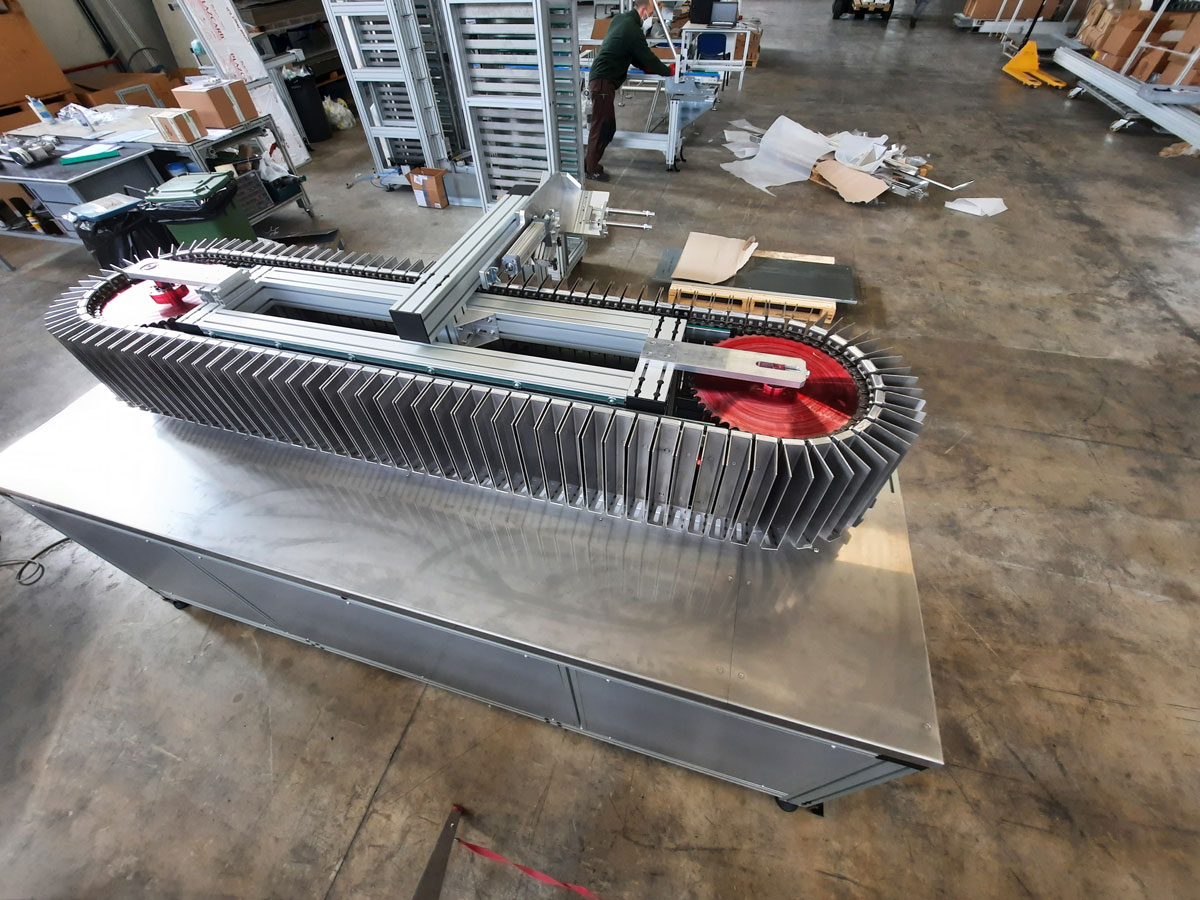

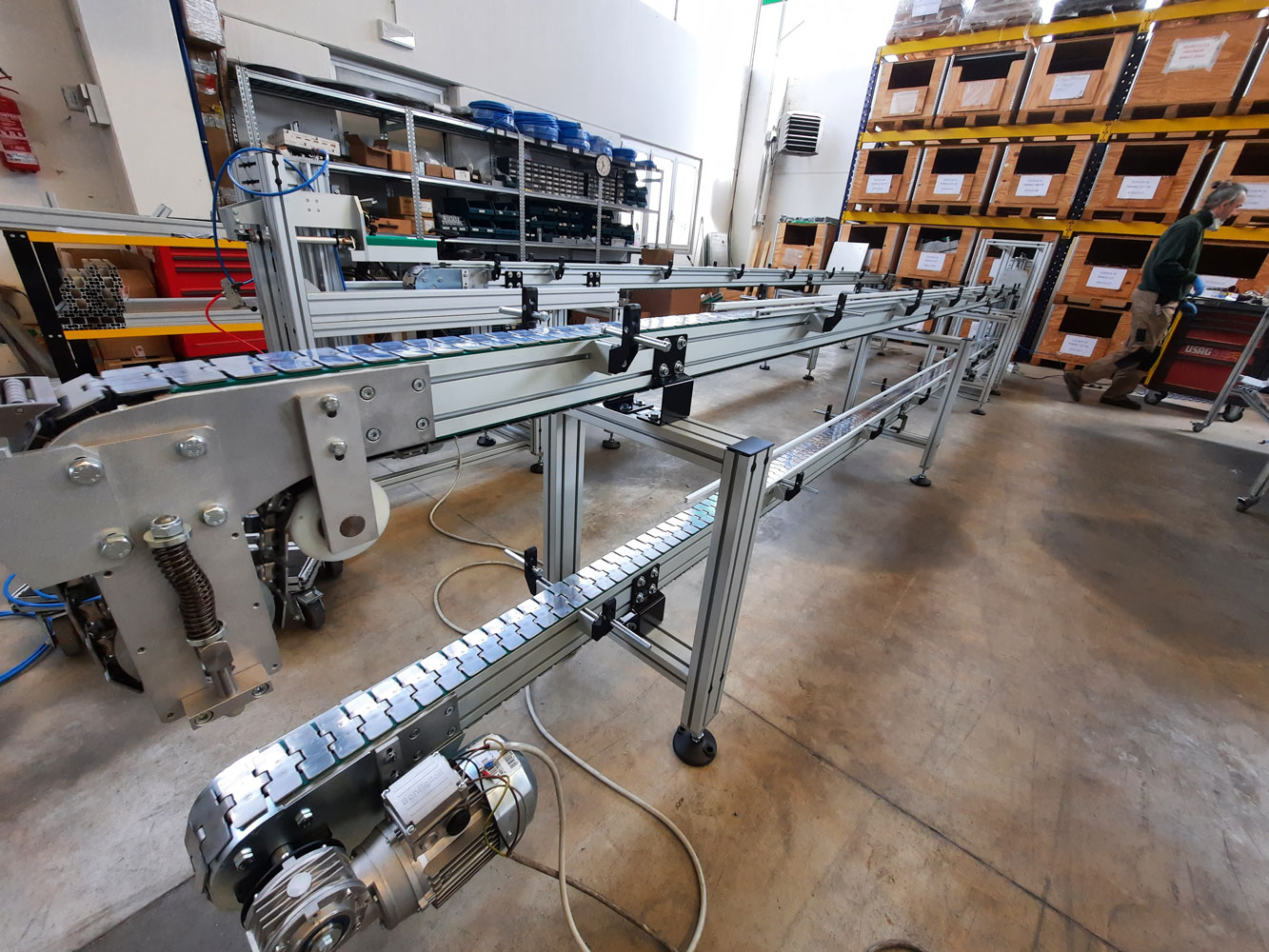

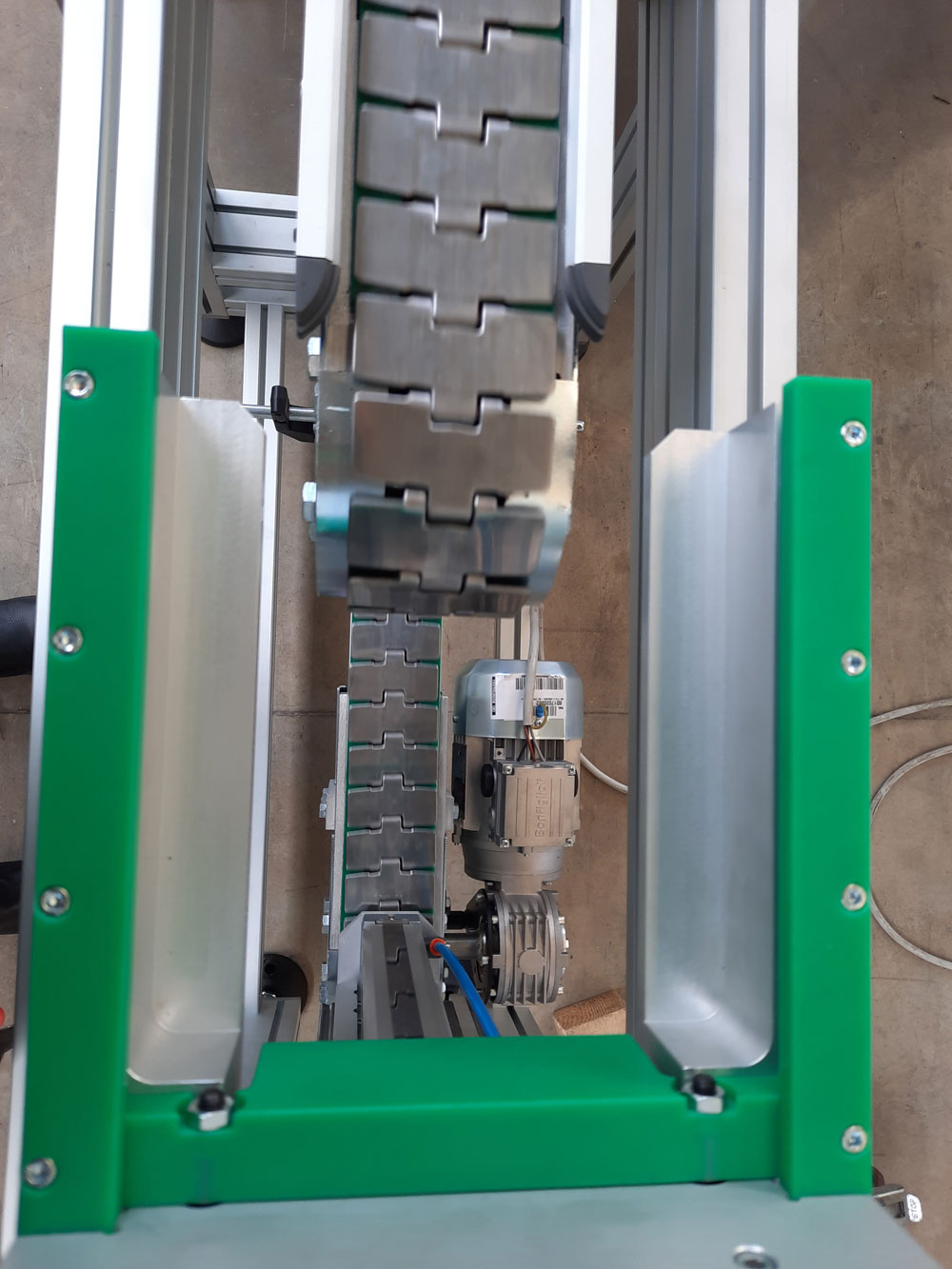

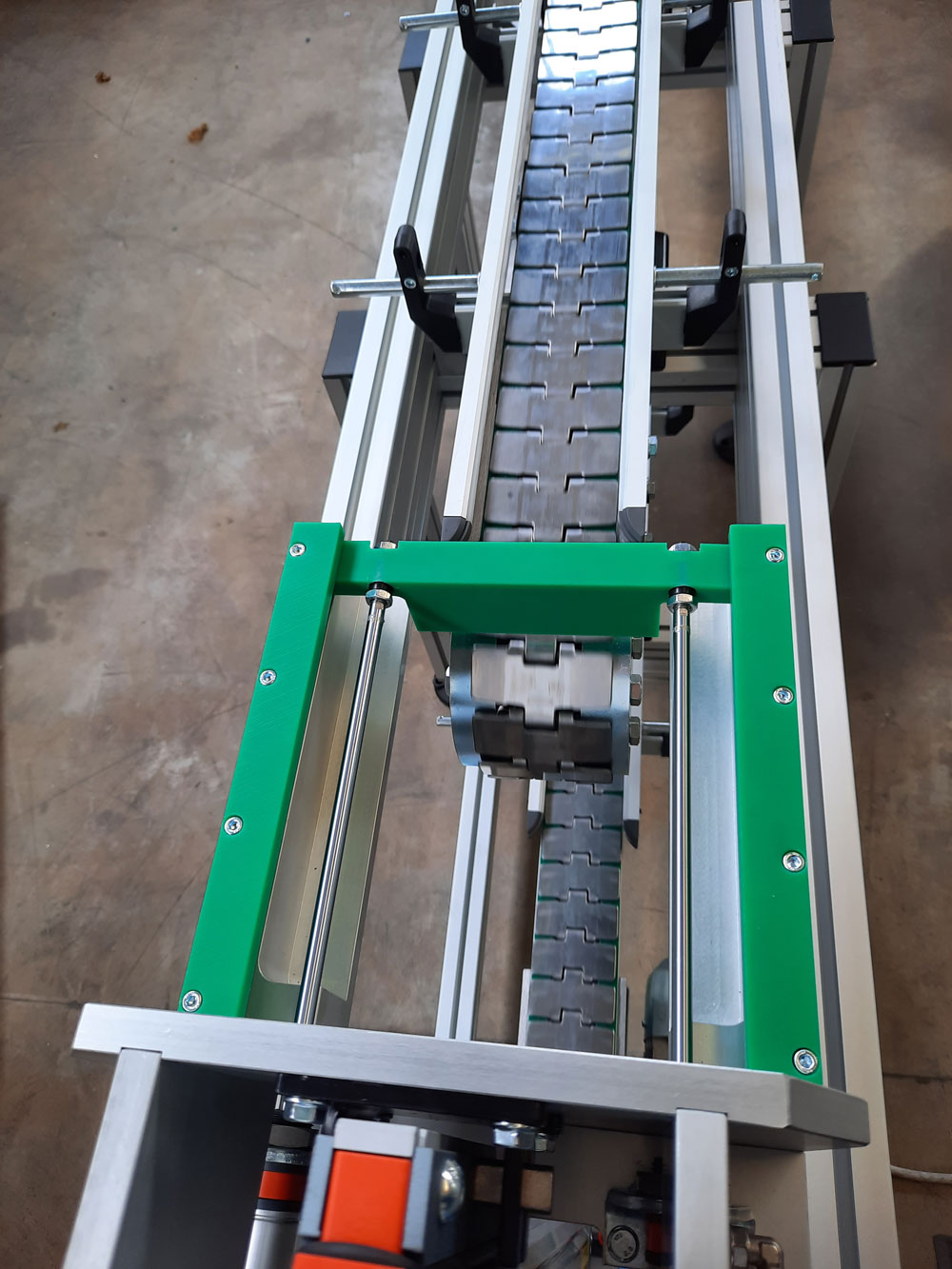

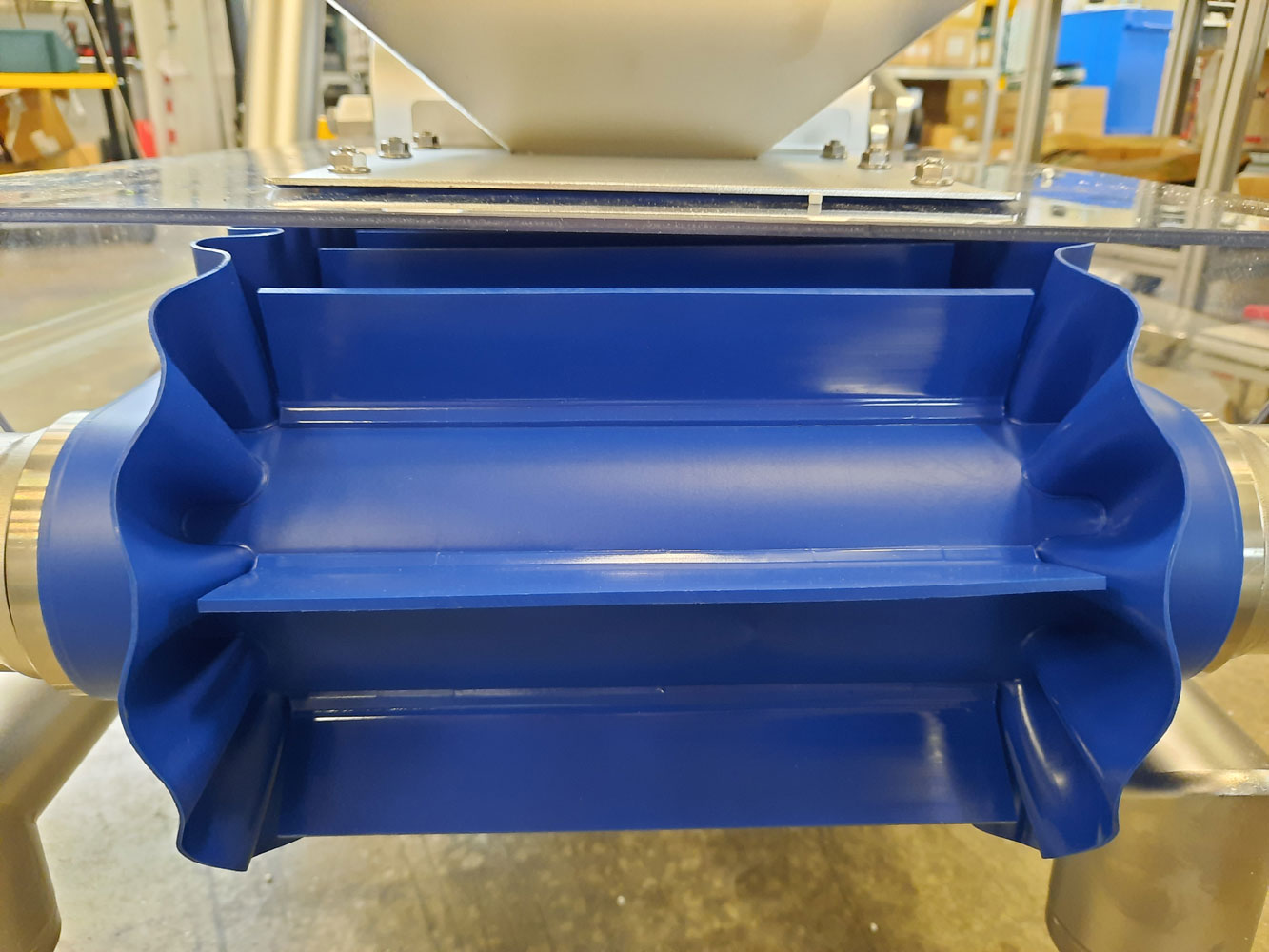

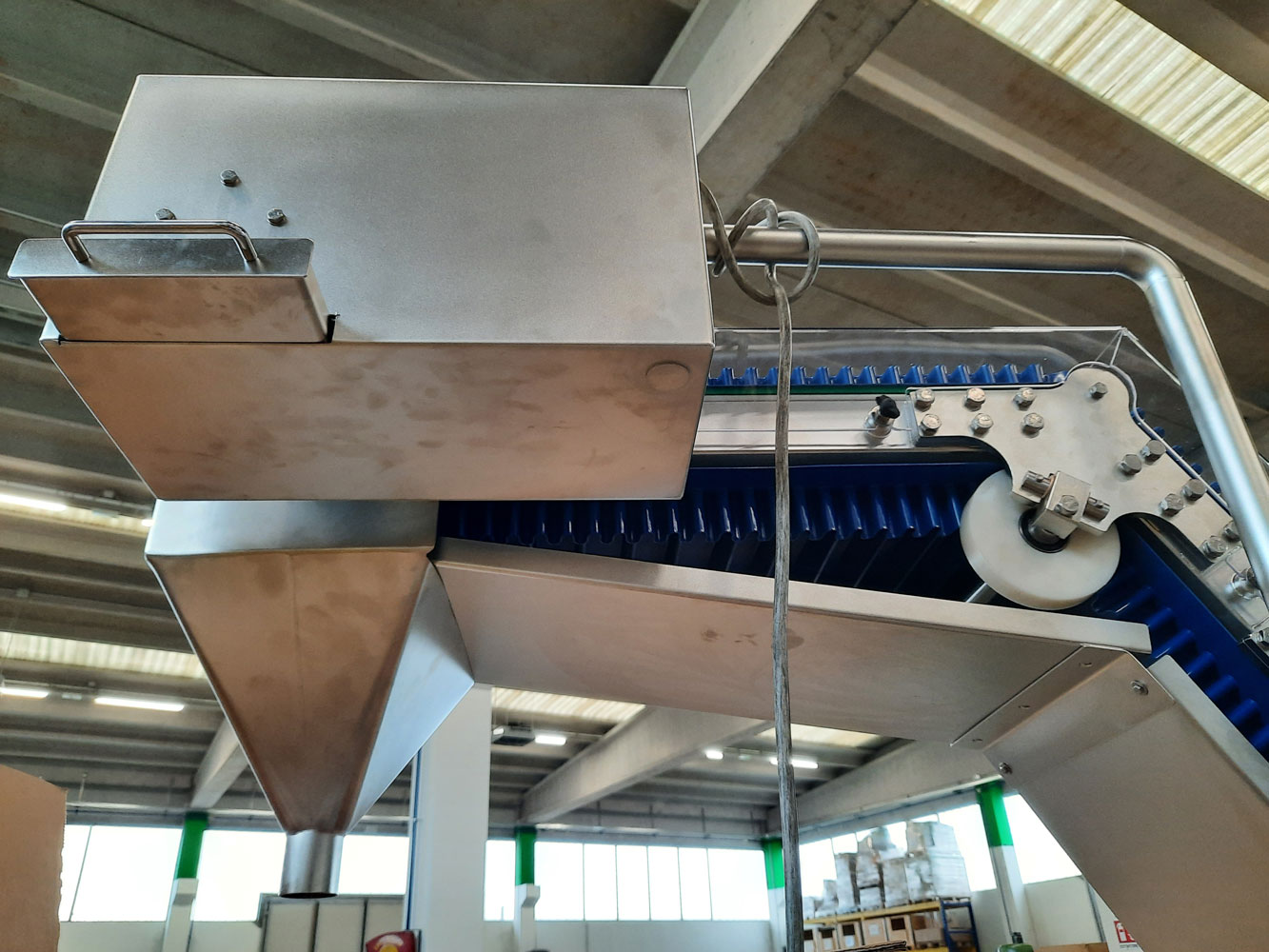

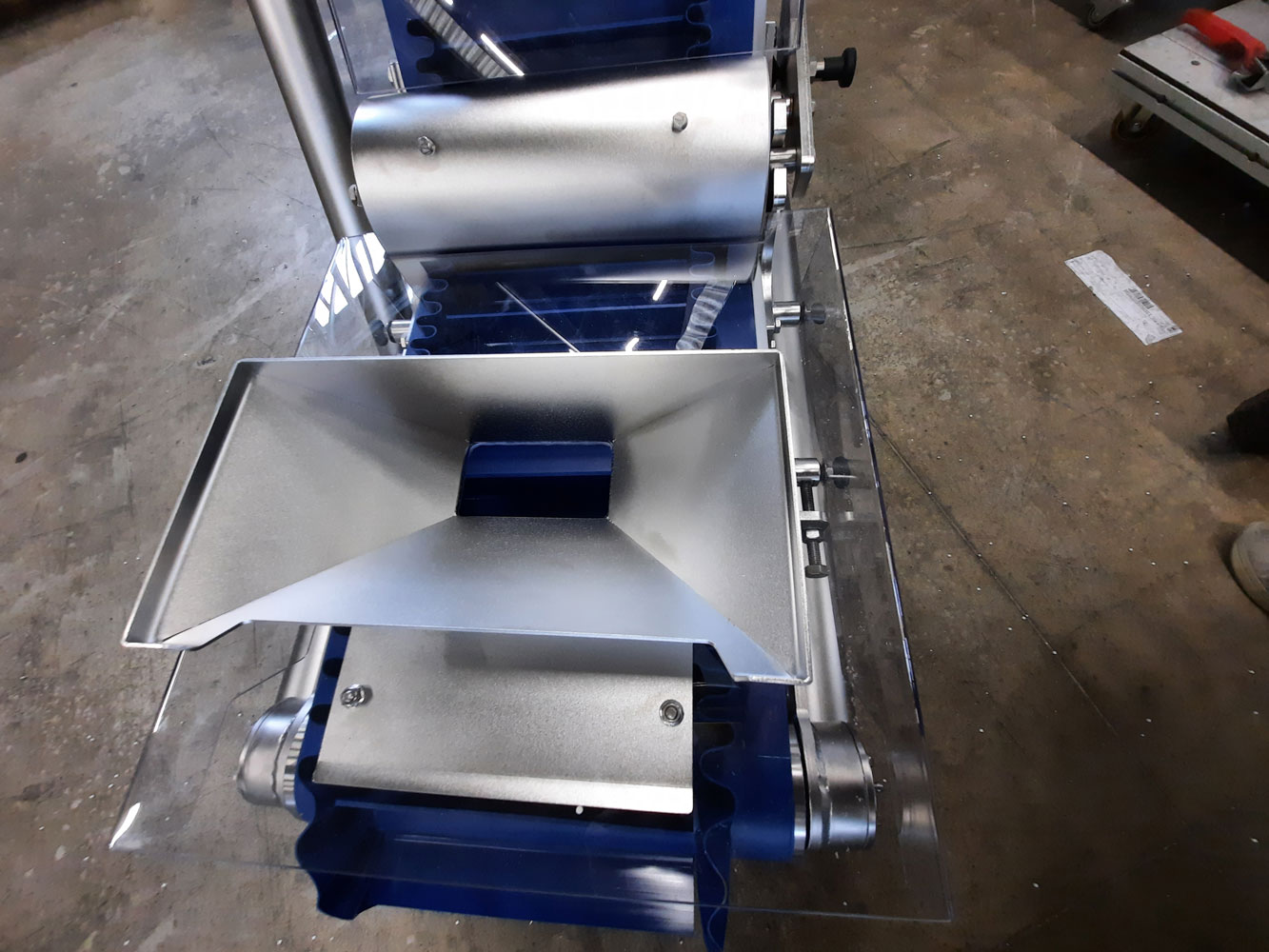

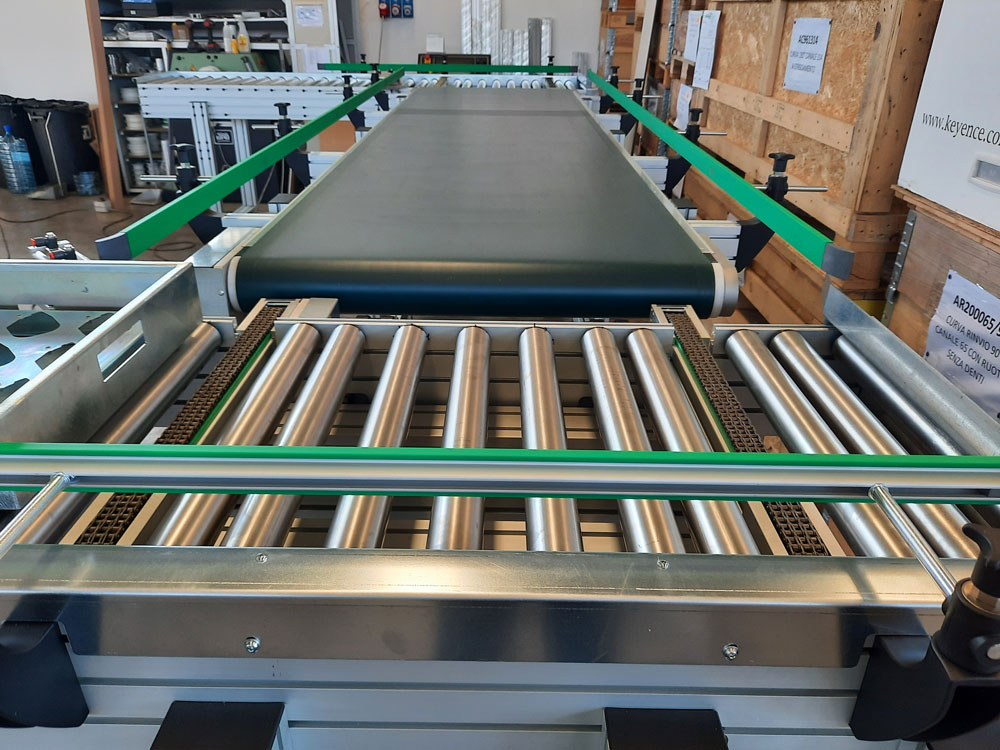

Motorized roller conveyor for transporting trays

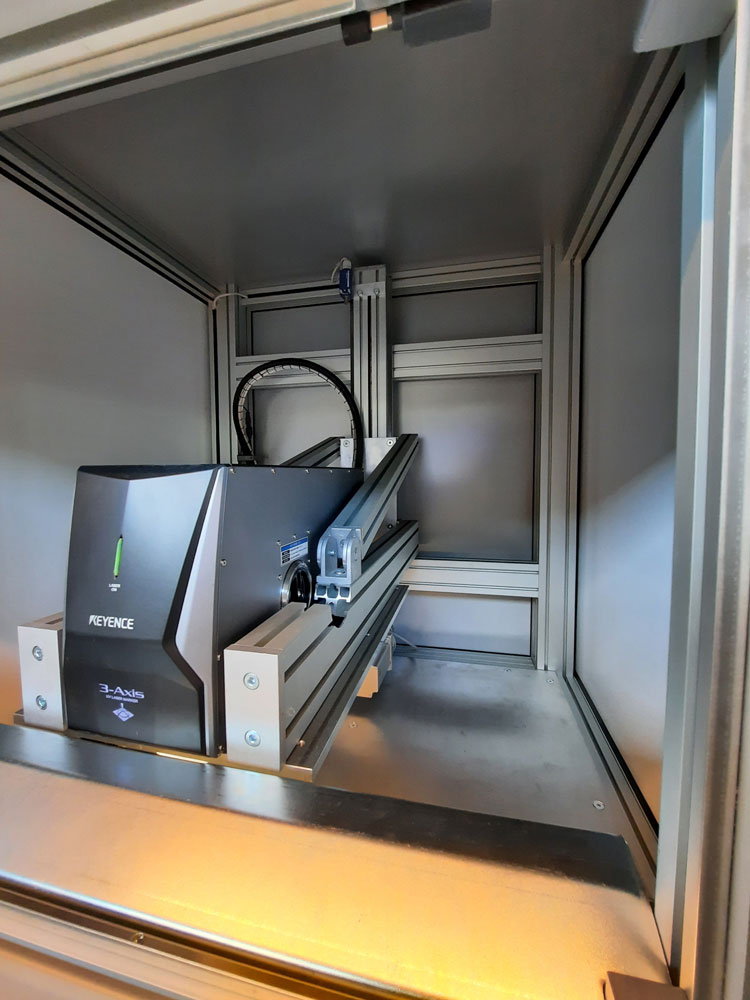

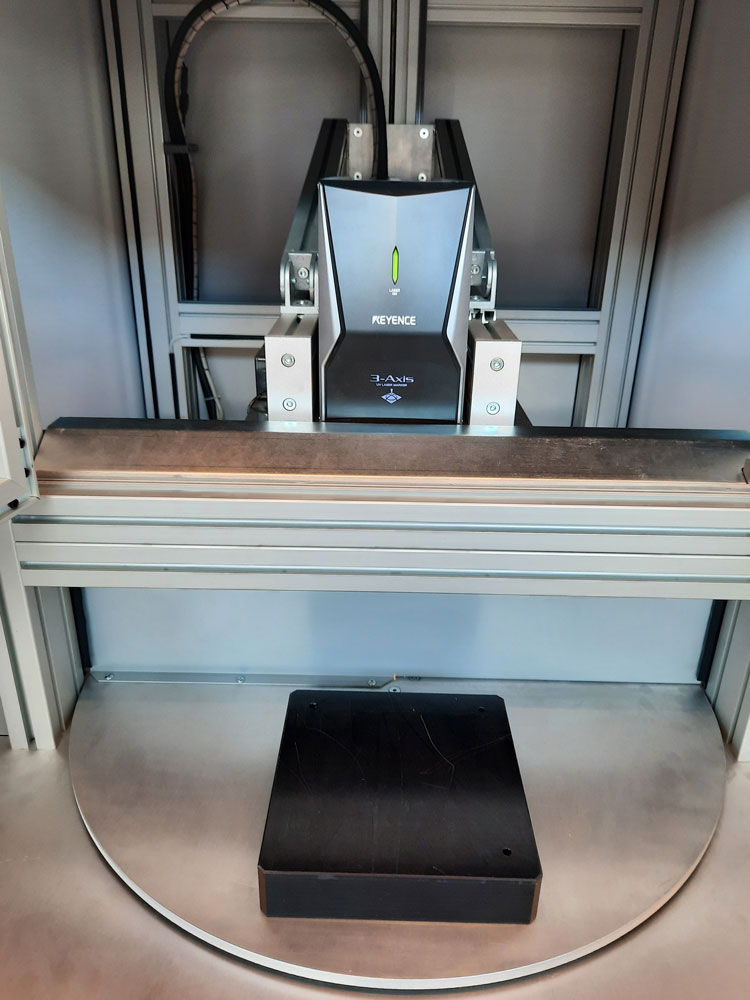

We have designed this motorized roller conveyor for transporting trays, with stainless steel rollers (diameter of 50mm), chain transmission with motorisation. At the end of the roller conveyor there is a polythene guide for the stop and an elevator with transmission to direct the tray towards the PVC belt.

For building the structure we have used Alutec 45×90 and 18.5×180 aluminium profile, There are also manually adjustable extensions to resize the tray passage.

-

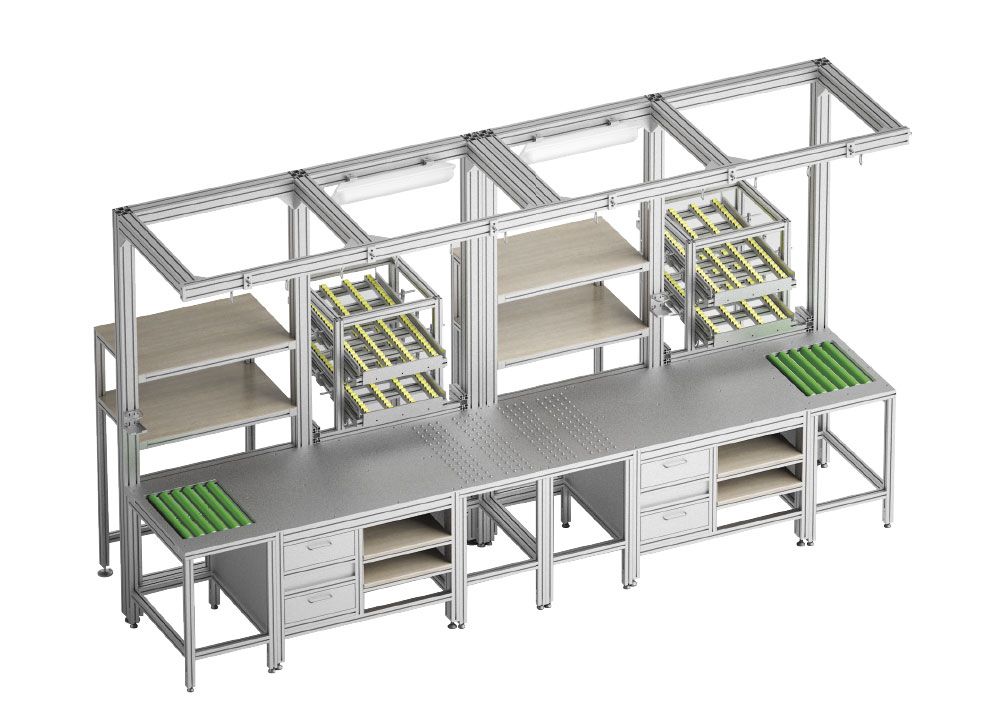

Motorized roller conveyor for transporting trays

-

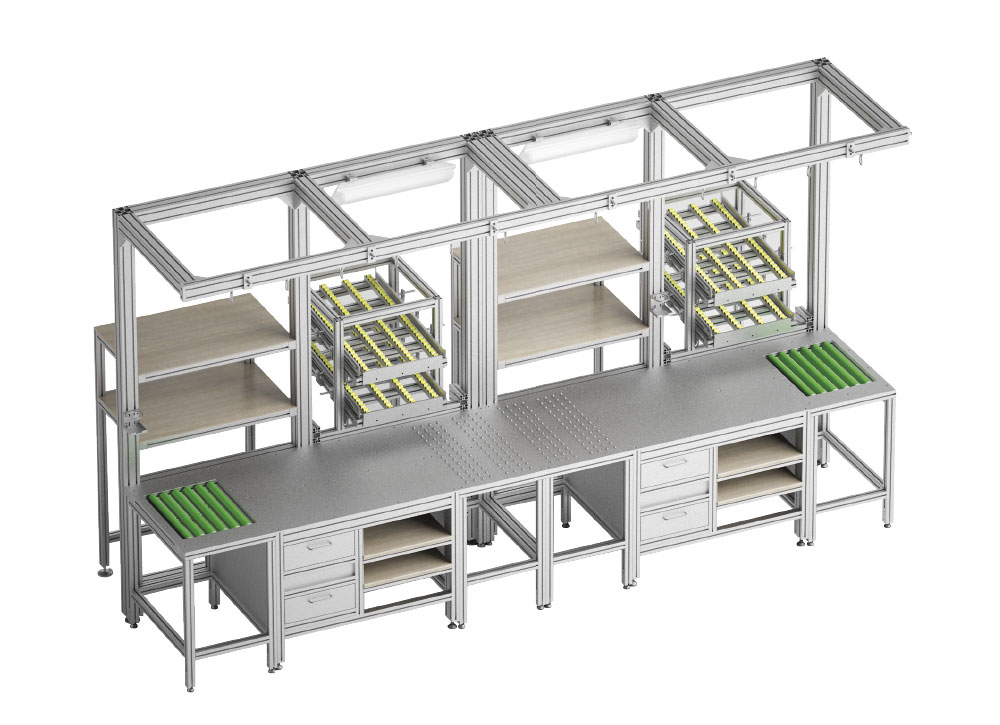

Motorized roller conveyor for transporting trays

-

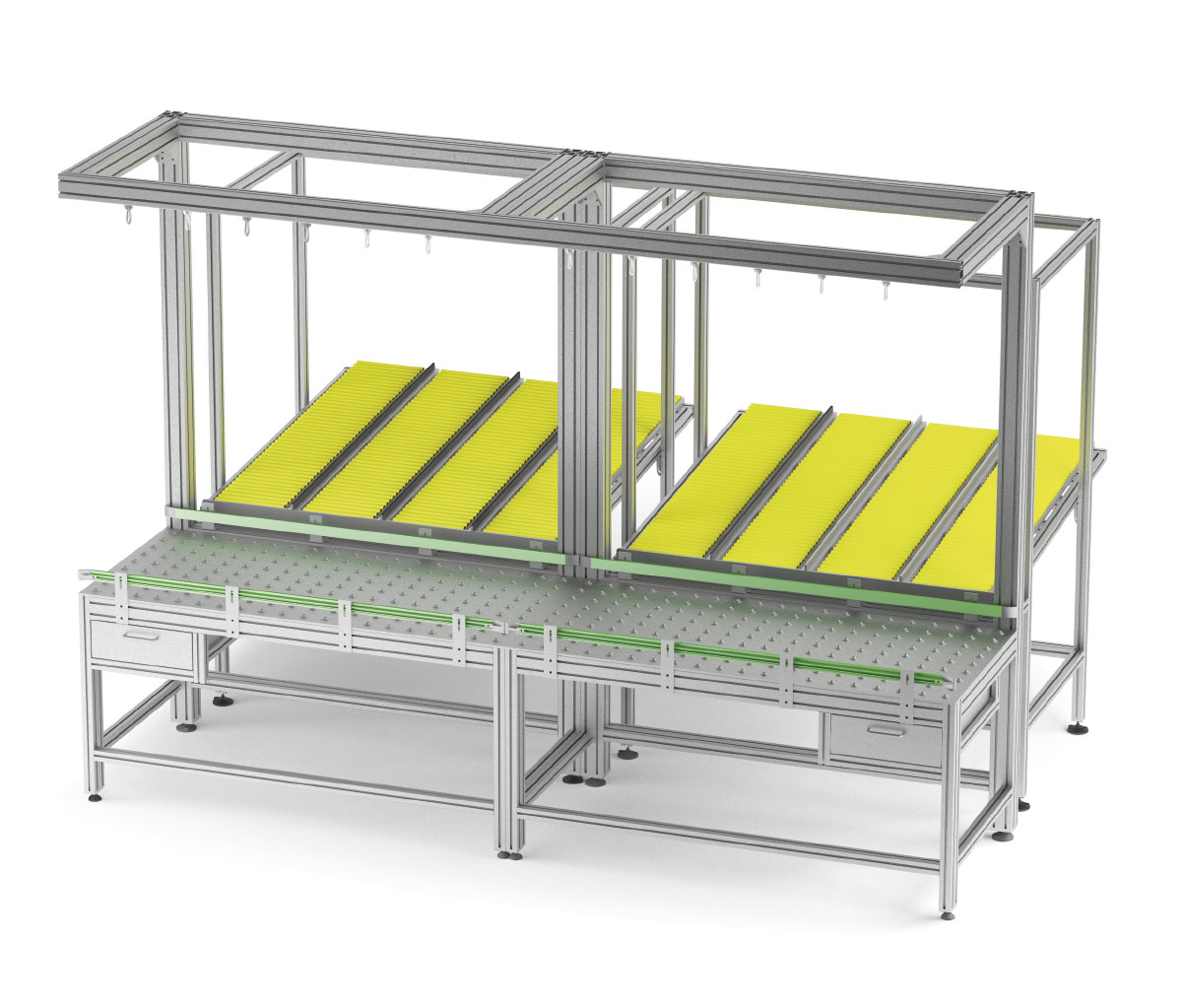

Motorized roller conveyor for transporting trays

-

Motorized roller conveyor for transporting trays

-

Motorized roller conveyor for transporting trays

CONTACT US FOR MORE INFORMATION